- Call us today

- +91 9930439474

- Email us now

- kamlesh@dineshtube-india.com

TECHNICAL INFO

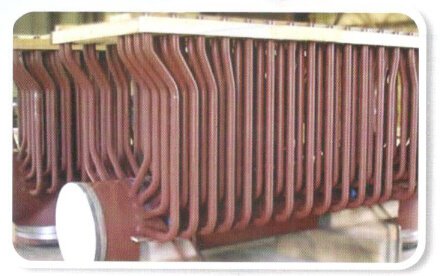

BOILER BANK TUBES

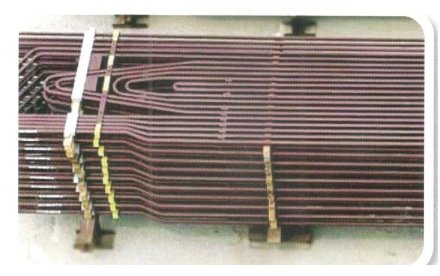

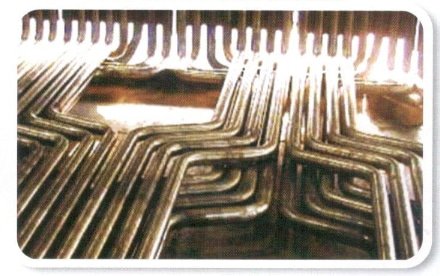

ECONOMISER COILS

SUPER HEATER COILS

WATER WALL PANELS

PRODUCT ATTRIBUTES

- SUPERIOR WELD QUALITY TO WITHSTAND END FLARING AND MANIPULATION OPERATION

- HYDRO TESTING AND ON-LINE EDDY CURRENT TESTING FOR CONFORMANCE TO WELD QUALITY

- BENDABILITY & DUCTILITY - HIGHER DEGREE OF MANIPULATION OPERATION

- UNIFORM GRAIN STRUCTURE - PREVENT PREFERENTIAL CORROSION

- FULLY KILLED CLEAN STEEL- ENSURES

- NO GAS POCKETS REMAIN IN STEEL AND TUBES, THAT CAN BE USED BEYOND 450°C TEMPERATURE, WHICH IS NOT POSSIBLE USING SEMI-KILLED STEEL

- ASER STENCILING FOR LONG LASTING TRACEABILITY

- BR SELF-CERTIFICATION - COMPLIANCE WITH IBR 1950 REGULATION

CUSTOMRERS SERVEDS

- INDUSTRIAL & COMMERCIAL BOILER MANUFACTURER

- FABRICATORS, REPAIRERS & RETUBERS OF BOILERS

- SUGAR MILLS

- POWER GENERATION

- HEAT RECOVERY STEAM GENERATION (HRSG)

- PULP & PAPER INDUSTRIES

- FERTILIZER INDUSTRIES

- CHEMICAL PLANTS

- PETRO CHEMICALS

- EDIBLE OILS MILLS

|

Chemical Composition,% (MAX Unless range is given)

|

Tensile Test

|

|||||||

|

Specification

|

C (%)

|

Si (%)

|

MN (%)

|

P (%)

|

S (%)

|

Tensile Strength Kgf/mm2

|

Yield Point Kgf/mm2,min.

|

Elongation

|

|

BS 3059-PART1 ERW320

|

0.16

|

0.35

|

0.030-0.070

|

0.040

|

0.045

|

320

|

195

|

25

|

|

BS 3059-PART2 ERW360

|

0.17

|

0.10-0.35

|

0.040-0.080

|

0.036

|

0.035

|

360

|

235

|

24

|

|

BS 3059-PART2 ERW360

|

0.13

|

|

0.60

|

0.050

|

0.050

|

300

|

200

|

20

|

|

BS 6323-PART5: 1982 ERW1 KM

|

0.13

|

|

0.60

|

0.050

|

0.050

|

280

|

115

|

25

|

|

BS 6323-PART5: 1982 ERW1 NKM

|

0.16

|

|

0.70

|

0.050

|

0.050

|

340

|

250

|

25

|

|

BS 6323-PART5: 1982 ERW2 KM

|

0.16

|

|

0.70

|

0.050

|

0.050

|

340

|

195

|

255

|

|

ASTM A423 GRADE 1

|

0.2

|

0.1

|

0.55

|

0.06-0.16

|

0.06

|

415

|

225

|

25

|

|

ASTM/ASME

|

EUROPEN UION

|

GERMANY

|

JAPAN

|

||||||||||||

|

SA/106

|

|

|

SA/A209

|

SA/A210

|

SA/A213 SA/A213

|

EN

|

DIN

|

JIS

|

UK/BIN

|

||||||

|

EN-10216-2

|

EN-10216-4

|

|

DIN 17173

|

DIN 17176

|

DIN 17175

|

3641

|

3456

|

3456

|

|||||||

|

GR.A

|

SA/A179

|

SA/A192

|

|

|

|

|

P23GH

|

|

|

|

ST358

|

STPT 38

|

3458

|

3456

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3456

|

|||

|

GR.B

|

|

|

|

SA/A210CR.C

|

|

P266GH

|

|

|

ST45.8

|

3456

|

|||||

|

GR.C

|

|

|

|

SA/A210CR.A

|

|

16MO3

|

|

|

|

17MO4

|

3456

|

||||

|

|

|

|

T1/T1A

|

|

P1

|

|

|

|

15MO3

|

3456

|

|||||

|

|

|

|

|

|

T5/T5

|

X11CRMO5

|

|

|

|

16MO3

|

STBA 12

|

STBA 12

|

3456

|

||

|

|

|

|

|

|

|

X11CRMO5

|

|

|

|

STAB26

|

STAB26

|

3456

|

|||

|

|

|

|

|

T9/P9

|

X11CRMO9-10

|

|

|

X2CRMO5

|

3456

|

||||||

|

|

|

|

|

|

|

|

|

X12CRMO91

|

STAB22

|

STAB22

|

3456

|

||||

|

|

|

|

|

T11/P11

|

10CRMO55

|

|

|

|

|

3456

|

|||||

|

|

|

|

|

|

|

|

|

|

|

12CRMO195

|

STBA 24

|

STBA 24

|

3456

|

||

|

|

|

|

|

T12/P12

|

13CRMO55

|

|

|

|

|

3456

|

|||||

|

|

|

|

|

|

|

|

|

|

13CRMO44

|

STBA 28

|

STBA 28

|

3456

|

|||

|

|

|

|

|

|

T22/P22

|

10CRMO9-10

|

|

|

|

STBA 22

|

STBA 22

|

3456

|

|||

|

|

|

|

|

|

|

|

|

|

|

10CRMO9-10

|

|

|

3456

|

||

|

|

|

|

|

|

T91/P91

|

X11CRWONO9-1

|

|

|

|

|

10CRMO9-1

|

|

|

3456

|

|

|

|

|

|

|

|

T92/P92

|

X11CRWONO9-2

|

|

|

|

|

|

|

3456

|

||

|

|

|

|

|

|

T23/P23

|

X11CRWONO9-4

|

|

|

|

|

|

|

3456

|

||

|

|

|

|

|

|

T36/P36

|

X11CRWONO5-6-4

|

|

|

|

|

|

|

3456

|

||

|

|

|

SA/A333 GR.1

|

|

|

|

P215NL/P255 QL

|

TST35NV

|

|

|

|

3456

|

||||

|

|

|

SA/A333 GR.6

|

|

|

|

|

|

|

|

|

|

|

|

3456

|

|

Specification Of Equivalent Standards

BS 3059 PT-2

EN 10217 PT-1 & 2

ASTM A178

ASTM A214

EN 10217 PT-2 & 3

EN 10217 PT-1 & 2

ASTM A178

ASTM A214