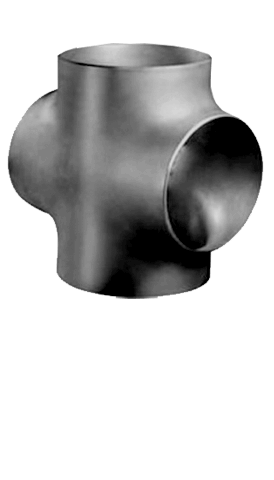

Alloy Steel WP91 Pipe Elbow, Alloy Steel WP91 Butt weld Elbow, ASTM A234 Alloy Steel WP91 Equal Tee, CrMo WP91 Pipe Fittings, Alloy Steel WP91 Reducer, Chrome Moly WP91 Pipe Cap Exporter, Alloy Steel WP91 Butt weld Fittings Supplier in Mumbai, India.

Dinesh Tube India is an ISO certified company, supplying and exporting the wide range of pipe fittings. We include high-quality Alloy Steel WP91 Pipe Fittings in various designations, specifications and custom dimensions so one can get products instantly. We work with the heart purpose of providing maximum clients satisfaction with our products. Whether small or big orders, we respect all our clients and every order is provided to customers on a set period of time.

ASME SA234 Alloy Steel WP91 Cross Stockists, Alloy Steel WP91 Pipe Bend, Chrome Moly WP91 Stub End, WP91 Long Radius Elbow, Alloy Steel WP91 Pipe Nipple, Alloy Steel WP91 Seamless Pipe Fittings, ANSI B16.9 WP91 Welded Pipe Fittings Supplier in India.

Mechanical data-

These pipe fittings play a central role in designing sections in industrial pipe fitting with desired attributes. These pipe fittings does not contain weld joints and seams. These are capable of up to an intense level of pressures and also in temperatures. These can be easily modified into any complex design thanks to flexibility. However, these are better in corrosion resistance while opposing high pressures. The weight of alloy steel is low hence handling turns easy. These are easily machined with standard machines with low cutting speeds, feed and cut depth, so it is a cost-effective option for industrial applications.

We use latest and trending machines for fabricating Alloy Steel WP91 Seamless Pipe Fittings. These are both hot or cold forged. Annealing or hot working process is considered to retain mechanical attributes. Usually, these are cold worked to avoid brittleness.

Quality policy-

We are committed to continuously improve the quality of products to create value for customers. We perform different tests on products to ensure the quality of products. The impact tests we perform are the destructive/nondestructive test, mechanical test, hardness test, tensile test, and positive material test. Other tests are Spectro analysis, intergranular corrosion test, ultrasonic test, radiographic test, pitting corrosion test and visual inspection.

Above tests are performed under the guidance of professionals considering the global standards. Thus, we are able to achieve goals demanded by the customers.

In order to offer damage free products to customers, we use standard packaging techniques to avoid damages while exporting. Alloy Steel WP91 welded Pipe Fittings are delivered in the form of bundles in cut size length also these are placed in the wooden cases or pallets.

Chemical Composition

Mechanical Properties