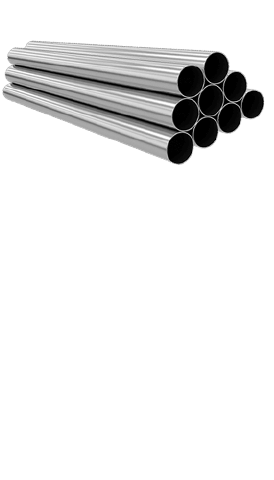

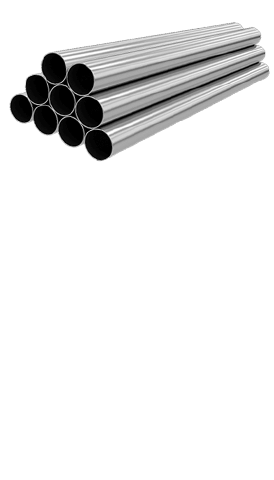

Cupro Nickel 70/30 Pipes Best Price, UNS C71500 Pipes, ASTM B466 70/30 Cupro Nickel Pipe, ASTM B466 Cupro Nickel 70/30 EFW Pipe, Cu-Ni 70/30 Pipes, 2.0882 Pipe, Cupro Nickel 70/30 Pipes Stockist, Cupro Nickel 70/30 Pipe, Cupro Nickel 70/30 ERW Pipes, ASME B466 70/30 Cupro Nickel Seamless Pipes, Cupro Nickel 70/30 Welded Pipe Supplier in Mumbai, India.

Dinesh Tube India is one of the largest and leading exporters and suppliers of high-quality CuNi 70/30 Pipes. The pipes are exported efficiently to avoid any severe damage. The enterprise is a favourite among buyers due to its valuable services. Some benefits include high-end finishing, accurate dimensions, good fabricability, and timely product delivery. Apart from this, the industry has been upgrading its product regularly to fulfil the buyers' demands. The raw materials used by the industry are bought from reliable market vendors to enhance the productivity of the pipes.

Table of Content

- What is Cupro Nickel 70/30 Pipes

- Cupro Nickel 70/30 Pipe Equivalent Grades

- Standard Specification For Cupro Nickel 70/30 Pipes

- Types Of Grades 70/30 Cupro Nickel Pipes

- Chemical Composition of Cupro Nickel 70/30 Pipe

- Mechanical Properties of 70/30 Cupro Nickel Pipe

- Widest Stock of 70/30 Cupro Nickel Pipe

- Application for Cupro Nickel 70/30 Pipe

- People Also Searched for

- Export Destinations for Cupro Nickel 70/30 Pipe

Cupro Nickel C71500 Pipe, Cupro Nickel 70/30 Pipe Stockholder, Cupro Nickel 2.0882 Pipes, Cupro Nickel 70/30 Round Pipes, 70/30 Cupro Nickel Rectangular Pipe, Cupro Nickel 70/30 Welded Pipes, Cupro Nickel 70/30 Square Pipes, Cupro Nickel 70/30 Oval Pipe, High Quality of 70/30 EFW Pipe, 70/30 Cupro Nickel Hollow Pipe, Cupro Nickel 70/30 Seamless Pipes, Cupro Nickel 70/30 Industrial Pipes Exporter in India.

Copper-nickel alloy is used in almost every industrial application due to its highly unmatched qualities and characteristics. The alloy has approximately 2-3% nickel that helps improve the oxidation resistance seen in the air and steam environment. The general characteristics of this alloy, it exhibits excellent thermal resistance and stability and moderate strength in high elevated temperatures.

Alloy's excellent corrosion resistance and superior strength due to the presence of manganese, iron, molybdenum, and chromium offer great fabricability and high inherent resistance in various befouling industries. The excellent solubility of nickel in copper makes it the best and most efficient copper-nickel alloy having a single-phase alpha structure. The Cu-Ni 70-30 alloy has been used widely in various industrial applications. The 70-30 fusion makes it right resistive against seawater corrosion. This is due to a high amount of iron and manganese.

We offer several documents along with the CuNi 70/30 Pipes so that the buyers can be assured about the quality and properties provided by the enterprise. The submitted papers are welding procedure specification, fumigation certificate, material test certificate, raw material report, QAP, heat treatment chart and guarantee letter, some of the documents offered along with the pipes. Regarding the material testing of the CuNi 70/30 Pipes, industry professionals conduct several material tests to ensure the quality and efficiency of the lines before finally delivering them to clients worldwide. The mechanical test, PMI, IGC, and other essential material tests are performed.

Equivalent Grades