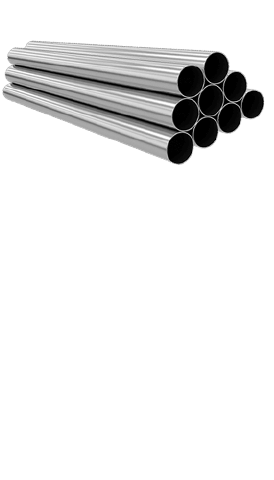

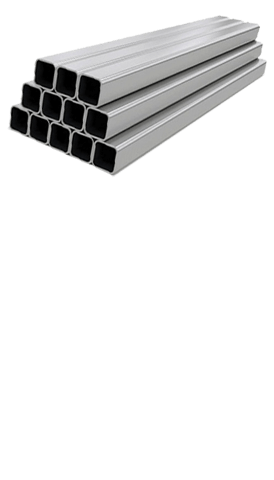

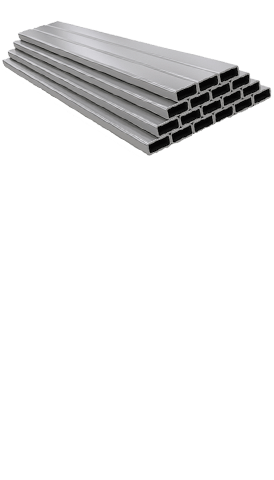

Cupro Nickel 95/5 Pipes Best Price, UNS C70400 Pipes, ASTM B466 95/5 Cupro Nickel Pipe, ASTM B466 Cupro Nickel 95/5 EFW Pipe, Cu-Ni 95/5 Pipes, Cupro Nickel 95/5 Pipes Stockist, Cupro Nickel 95/5 Pipe, Cupro Nickel 95/5 ERW Pipes, ASME B466 95/5 Cupro Nickel Seamless Pipes, Cupro Nickel 95/5 Welded Pipe Supplier in Mumbai, India.

The copper-nickel alloy is the short resistivity alloy used at temperature range up to 300°C (570°F). The alloy is mostly used in heating cables in electric pillows and blankets. The medium resistivity and low-temperature co-efficient of the fight also make these alloys ideal for manage resistors and thermocouples. The C70400 Copper-Nickel alloy is brilliant on hot and cold workability and is resistant towards atmospheric, brackish water, sea water, and non-oxidizing acid corrosion.

Table of Content

- What is Cupro Nickel 95/5 Pipes

- Cupro Nickel 95/5 Pipe Equivalent Grades

- Standard Specification For Cupro Nickel 95/5 Pipes

- Types Of Grades 95/5 Cupro Nickel Pipes

- Chemical Composition of Cupro Nickel 95/5 Pipe

- Mechanical Properties of 95/5 Cupro Nickel Pipe

- Widest Stock of 95/5 Cupro Nickel Pipe

- Application for Cupro Nickel 95/5 Pipe

- People Also Searched for

- Export Destinations for Cupro Nickel 95/5 Pipe

High Quality of 95/5 EFW Pipe, 95/5 Cupro Nickel Hollow Pipe, Cupro Nickel 95/5 Square Pipes, Cupro Nickel 95/5 Welded Pipes, Cupro Nickel 95/5 Seamless Pipes, Cupro Nickel C70400 Pipe, 95/5 Cupro Nickel Rectangular Pipe, Cupro Nickel 95/5 Pipe Stockholder, Cupro Nickel 95/5 Round Pipes, Cupro Nickel 95/5 Oval Pipe, Cupro Nickel 95/5 Industrial Pipes Exporter in India.

We at dinesh tube India offer our customers in varied shapes and sizes. CuNi6 is a copper-nickel alloy (CuNi alloy) among low resistivity suitable for use at temperature up to 300°C (570°F). The alloy is used in forming wires that are normally used for low- temperature applications such as heating cables. The C70600 copper Nickel is the alloy that offers corrosion resistance in seawater environments. The alloy contains 10- 30 percent of nickel with the addition of iron and manganese, which are needed to maintain resistance towards corrosion.

The C70400 Copper Nickel 70/30 alloy is the corrosion opposed to alloy mainly in a seawater environment. The alloy is the arrangement of nickel, iron, and manganese that helps in maintains good corrosion resistance and is normally used in valves, and pump components. This form of copper-nickel tubes produced by tube tech possesses exceptional resistance to corrosion by salt water as well as elevated resistance to erosion corrosion and air-impingement attack. The addition of iron results in 90/10 performing as well as 70/30 in seawater service heat exchangers. These tubes have good quality strength and ductility at ordinary temperatures and reasonably high strength and other mechanical properties at important temperatures.

The industry offers several documents along with the CuNi 95/5 Pipes so that the buyers can be assured about the quality and properties that have been provided by the enterprise. The submitted documents are welding procedure specification, fumigation certificate, material test certificate, raw material report, QAP, heat treatment chart and guarantee letter are some of the documents offered along with the pipes. Talking about the material testing of the CuNi 95/5 Pipes, the industry professionals conducts several material tests in order to ensure the quality and efficiency of the pipes before finally delivering it to the clients across the world. Tests performed are the mechanical test, PMI, IGC, and other essential material tests.

These copper nickel tubes are generally used in condensers, coolers and heat exchangers where the struggle to corrosion and corrosion is paramount, yet maintaining a high thermal conductivity rate. To be used if possible in marine conditions. It Forms a defensive film which is multi-layered in flowing salt water. These copper nickel tubes are produced inside a range of outside diameter, wall thickness a variety of temper conditions to achieve the necessary mechanical properties and grain size. The mechanical and dimensional characteristics of our products please the most demanding orders that need tight tolerances.

Equivalent Grades