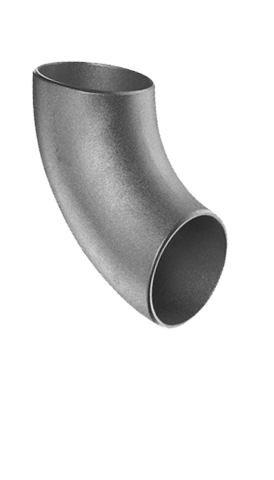

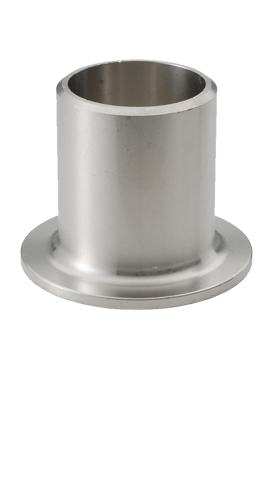

SS 316L Butt weld Elbow, SS WP316 Pipe Fittings, Stainless Steel 316L Pipe Bend, SS 316 Reducer, SS 316L Pipe Cap Supplier, Stainless Steel 316L Pipe Elbow, Stainless Steel 316 Butt weld Fittings, ASTM A403 Stainless Steel 316 Equal Tee Exporter in Mumbai, India.

SS 316/316L Pipe Fittings the molybdenum content increase corrosion-resistance, improve resistance to pitting in chloride ion solutions and increases strength at high temperatures. Type 316 grade Stainless steel is mainly effective in acidic environments. Alloys regularly are extra to steel to raise desired properties. Sea grade Stainless steel called type 316, as opposed to certain types of interactions.

SS 316L Pipe Fittings, SS 316L Stub End, ANSI B16.9 Stainless Steel 316L Welded Pipe Fittings, Stainless Steel WP316L Pipe Nipple, ASME SA403 Stainless Steel 316L Cross Stockists, SS 316 Long Radius Elbow, Stainless Steel 316 Seamless Pipe Fittings Supplier in India.

There is a variety of dissimilar types of 316 Stainless sheets of steel, including 316 L, F, N, H, and several others. Each is slightly different, and each is used for dissimilar purposes. The "L" designation means 316L steel has less carbon than 316 steel.

Qualities of 316/316L-

It is the ordinary in the food industry both type of 316L and 316 show corrosion resistance and are stronger at important temperatures. They also are together non-hard enable by temperature treatment and can be with pleasure formed and drawn. Annealing 316 and 316L Stainless steel require heating to between 1,900 and 2,100 degrees Fahrenheit previous to rapidly quenching.

Types of 316-

Common uses of 316 Stainless steel comprise in the construction of exhaust manifolds, heater parts, heat exchangers, jet engine parts, pharmaceutical and photographic equipment, valve and pump parts, and chemical giving out equipment, tanks, and evaporators. It also is used in pulp, paper, and textile processing gear and any parts exposed to sea environments.

Type 316L Steel-

Type 316L Stainless steel is an extra-low carbon edition of the 316 steel alloys. The lower carbon satisfied in 316L minimizes deleterious carbide rainfall as a result of welding. Consequently, 316L is used when welding is necessary in order to ensure the greatest corrosion resistance.

Testing’s-

Mechanical Testing Such as Tensile of Area, Hardness Test, Micro, and Macro Test, Intergranular Corrosion (IGC) Test, Pitting Resistance Test, Positive Material Identification – PMI Testing, Flaring Test, Chemical Analysis – Spectro Analysis and Flattening Test.

Work hardenable grades of Stainless steel have the benefit that significant increases to the power of the metal can be achieved simply through cold working. A combination of cold work and annealing stages can be employed to give the made-up component a specific power.

A buyer seeking to the SS 316/316L Pipe Fittings can get the product at comprehensive range from Dinesh Tube India. They offer good quality of fittings at reasonable rates and assure timely and safer shipping of ordered product.

Equivalent Grades