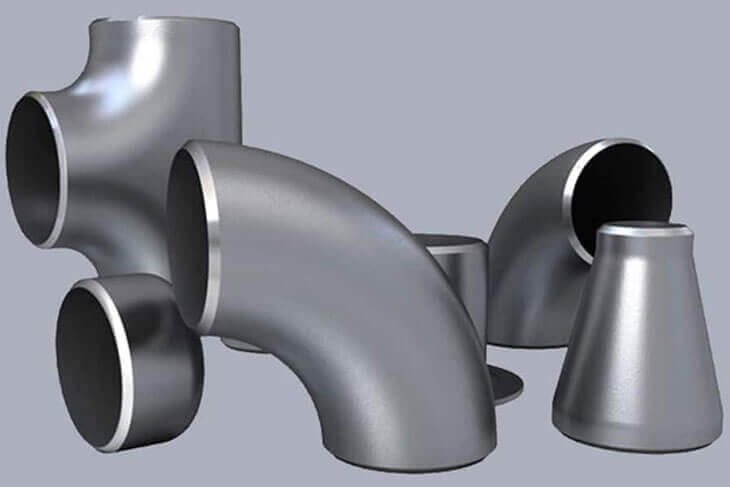

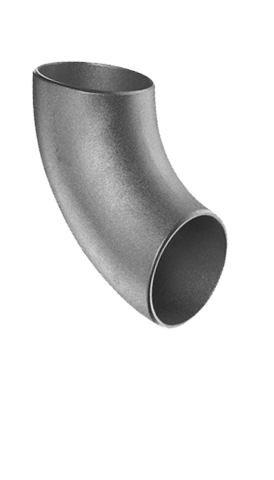

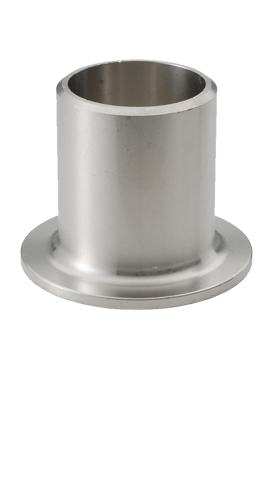

SS WP317 Pipe Fittings, SS 317L Butt weld Elbow, SS 317L Pipe Cap Supplier, ASTM A403 Stainless Steel 317 Equal Tee Exporter, Stainless Steel 317L Pipe Bend, Stainless Steel 317L Pipe Elbow, SS 317 Reducer, Stainless Steel 317 Butt weld Fittings in Mumbai, India.

SS 317L pipe fittings is a low carbon difference of alloy 317. This austenitic chromium-nickel Stainless steel is able to be used in applications anywhere it is not likely to anneal behind welding and where maximum corrosion battle is required. It provides good corrosion resistance in intermittent repair to 1600°F and in continuous service to 1700°F. SS 317 is a molybdenum-bearing austenitic alloy that comes with the greater battle to the chemical attacks in comparison to the common chromium-nickel alloys like SS 304 and SS 316L.

ASME SA403 Stainless Steel 317L Cross Stockists, SS 317 Long Radius Elbow, Stainless Steel 317 Seamless Pipe Fittings Supplier, ANSI B16.9 Stainless Steel 317L Welded Pipe Fittings, Stainless Steel WP317L Pipe Nipple, SS 317L Stub End, SS 317L Pipe Fittings in India.

Besides, 317 also offer greater strength level at raise temperatures i.e. higher creep, stress-to-rupture, and tensile power.

Alloy 317L is austenitic Stainless steel with low carbon satisfied that gives better corrosion resistance in contrast to 304L and 316L alloys. Due to less percentage of carbon, SS 317L is resistant to sensitization experienced during weld and other thermal procedures. In the annealed environment, alloy 317L can be non-magnetic, though the magnetic characteristics could return with welding.

Alloy 317L (UNS S31703) is low carbon corrosion opposed to austenitic chromium-nickel-molybdenum Stainless steel. The high levels of these elements give surety the alloy has superior chloride pitting and common corrosion resistance to the conventional 304/304L and 316/316L grades. The alloy provides improved struggle relative to 316L in strongly corrosive environments contain sulfurous media, chlorides, and other halides.

The low carbon satisfied of Alloy 317L enables it to be welded without intergranular corrosion resulting from chromium carbide precipitation enable it to be used in the as-welded condition. With the addition of nitrogen as an increasing agent, the alloy can be the dual expert as Alloy 317 (UNS S31700). Alloy 317L is non-magnetic in the annealed condition. It cannot be hardened by heat up treatment; however, the material will solidify due to cold working. Alloy 317L can be effortlessly welded and processed by standard shop fabrication practices.

The higher molybdenum satisfied of SS 317/317L Pipe Fittings assures superior common and localized corrosion resistance in mainly media when compared with other Stainless steels grades. Environments that don’t bother certain Stainless steel will usually not corrode 317L. One exception, however, is powerfully oxidizing acids such as nitric acid. Alloys that have molybdenum generally do not make as well in these environments.

Equivalent Grades