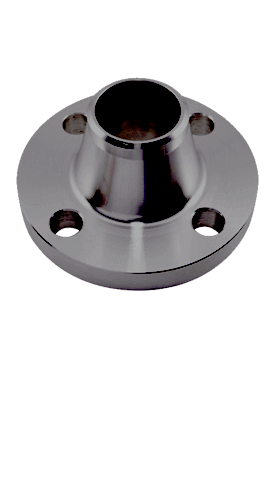

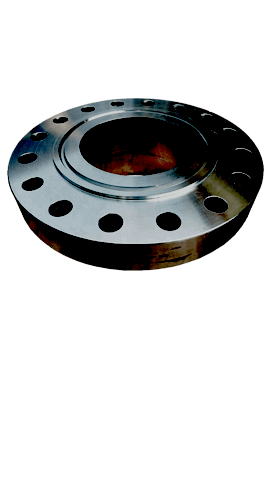

Alloy Steel F5 Slip on Flanges, Alloy Steel F5 Weld Neck Flanges, Alloy Steel F5 Flanges Exporter, Grade F5 CrMo Flanges, Alloy Steel F5 Blind Flanges, ASTM A182 Chrome Moly F5 Socket weld Flanges, CrMo F5 Lap Joint Flanges Supplier in Mumbai, India.

Dinesh Tube India is an ISO-certified company and registers with various international standards. We are supplying and trading a broad spectrum of flanges and stock high-quality Alloy Steel F5 Flanges. One can get them in multiple designations, specifications, and custom dimensions and demand any specific requirement for their sole purpose. We work with dedication to provide customers with high-quality products that satisfy their needs.

ANSI B16.5 Alloy Steel F5 Spectacle Blind Flanges Supplier, ASME SA182 Alloy Steel 5Cr-1/2Mo Threaded Flanges, CrMo F5 RTJ Flanges, Chrome Moly F5 Flanges, Chrome Moly F5 Long Weld Neck Flanges, Alloy Steel F5 Pipe Flanges Stockists in India.

Whether small or big orders, we take all orders from scale or large-scale industries and provide them in a set period. Alloy Steel F5 Flanges are delivered in the standard packing of wooden cases or pallets and are covered with a thin film of plastic to prevent rust.

Attractive attributes of Alloy Steel F5 Flanges:

These Alloy Steel F5 Pipe Flanges are vital in fitting heavy assemblies. Alloy steel flanges are a fitting that does not contain joints. These flanges are competent at up to a concentrated pressure level and also in elevated temperatures. These can be easily turned into complex design fittings because of their flexibility. However, these flanges have excellent oxidation resistance and abrasion resistance. These are low-weight flanges; hence the fitting does not become bulky and heavy. Alloy steel is easily machined with standard machining techniques. This requires low cutting speeds, feed, and cut depth. Thus, these are cost-effective options for industrial fitting applications.

We are equipped with advanced machines to fabricate Alloy Steel F5 Weld Neck Flanges. Hot or cold forming processes both are considered for fabrication. The Annealing process is deemed to retain mechanical properties before hot working. Meanwhile, flanges are cold-worked to avoid exhaustion.

Quality terms/ certificates-

We are praised for offering improved quality products to create value for customers. We perform various tests on flanges to ensure the excellence of products. The tests are performed under the guidance of professionals considering global standards. Therefore, we can attain the goals demanded by the customers. Some of the tests are destructive & nondestructive tests, mechanical tests, hardness tests, tensile tests, positive material tests, intergranular corrosion tests, ultrasonic tests, radiographic tests, and pitting corrosion tests.

Equivalent Grades